MDEC Modularization

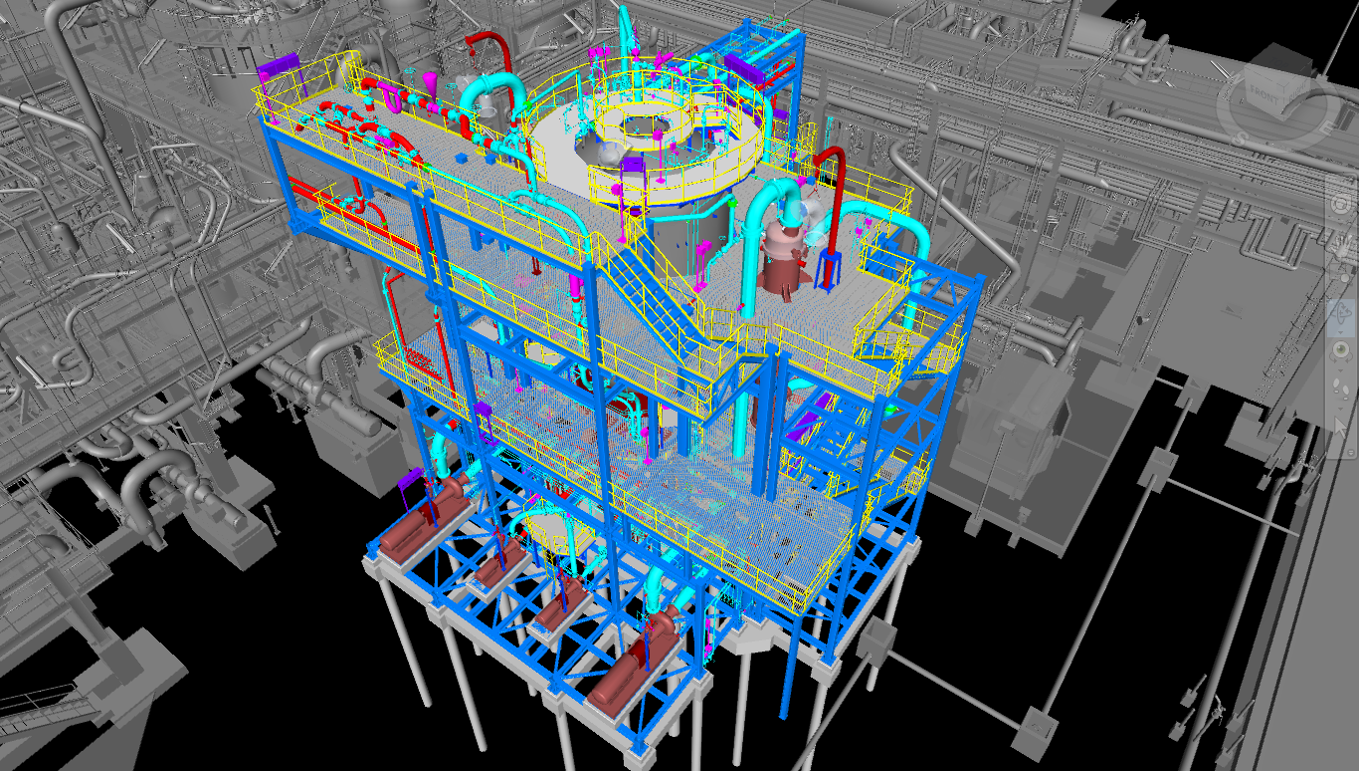

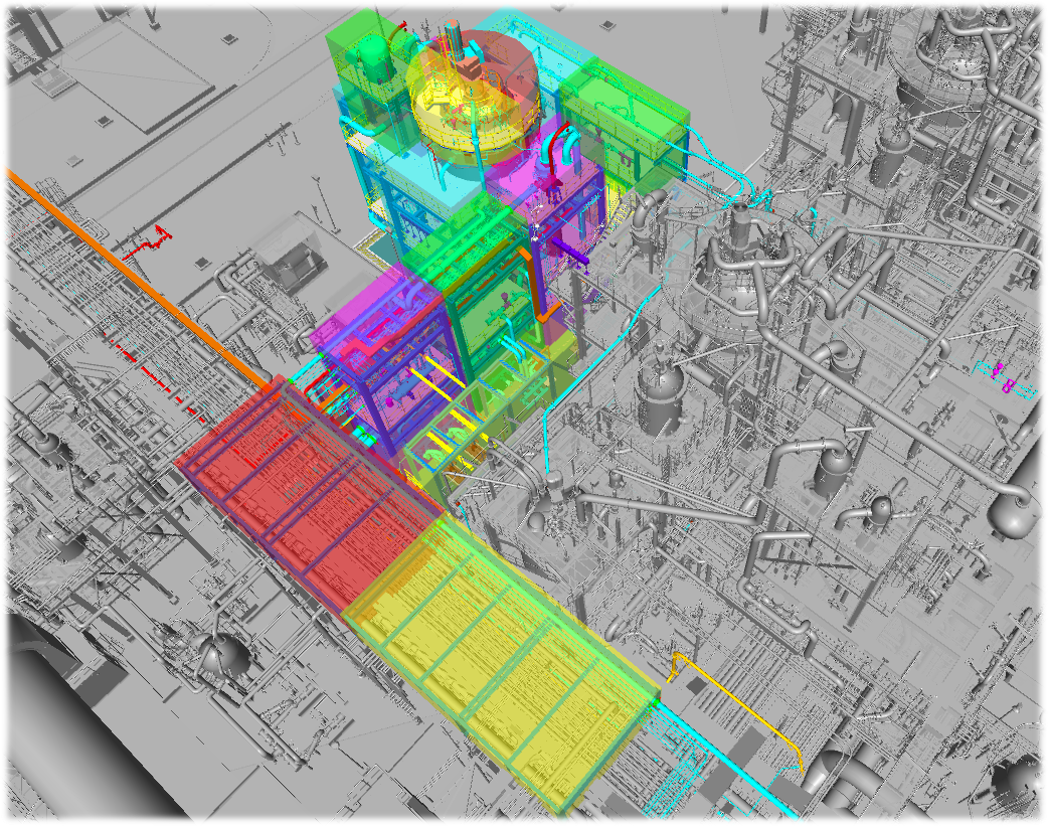

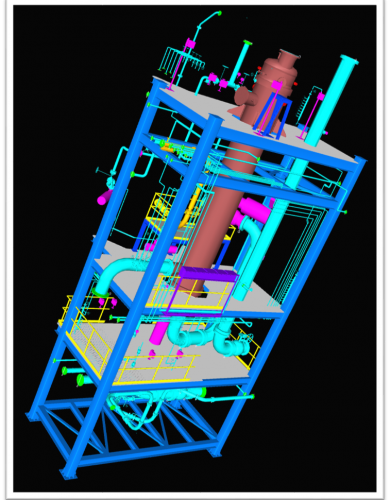

MDEC modularization is coming to the 4th Generation of design, fabrication, and construction. More than 90 percent of completing progress off-site yard by MDEC pre-fabrication and pre-assembly, that is effective with time limitation during on-site installation. MDEC Modular is a unit mounted on the structural steel framework, which can design into several sub-modular depend on size and capacity of modules. This modular contain mechanical equipment, piping system, electrical and instrumentation system, process tubing, costing and insulation, sub-station, and etc. With fully pressure test, flushing, reinstate and leak test, loop test can be done off-site and coming only “Plug & Play” on-site.

MDEC modular can be suited for many industries including petrochemical plant, oil and gas, sub-manufacturing process, and etc. MDEC team have the fully capability of design, engineering, construction, and management to support its customer, which be provided completely project phase that begin with Conceptual -> FEED -> Detailed Design Engineering and Procurement -> Fabrication -> Construction -> Turn-Over and Start-Up.

Advantage of MDEC modular

- Schedule Efficiency. A quick shutdown or turnaround period, MDEC modular concept can be constructed much faster than conventional construction.

- Cost Reduction. On-site indirect costs can be reduced including construction supervision, consumable, etc. Off-site labor cost is also cheaper than on-site construction.

- Quality. Easy to manage and control conditions, permanent established workforce and skilled worker.

- Risk and Safety Reduction. Minimizing risk effecting other plant operations during a construction. Less congestion and plant traffic.

MDEC Modular Products

- Modular Pre-Cast Foundation

- Modular Pre-Cast Concrete Wall

- Modular Pre-Cast Beam and U-ditch

- Modular Steel Pile and supported structure

- Modular Process Plant

- Modular Sub-Station

- Other modular